Computer Aided Engineering(CAE) Services

Introduction to CAE Services

Computer aided engineering (CAE) involves the use of computer software to improve product design and resolve engineering problems for a wide range of industries.

CAE is used to both design and support the engineering process for a product, allowing tests and simulations to be performed without the need for a physical prototype.

Bringing together engineering simulation and high-performance computing provides cost and time savings, in both the design and the overall product development process

Key Components of CAE

Simulation and Analysis

Design Optimization

Virtual Prototyping

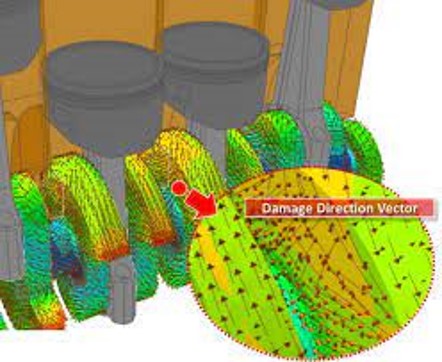

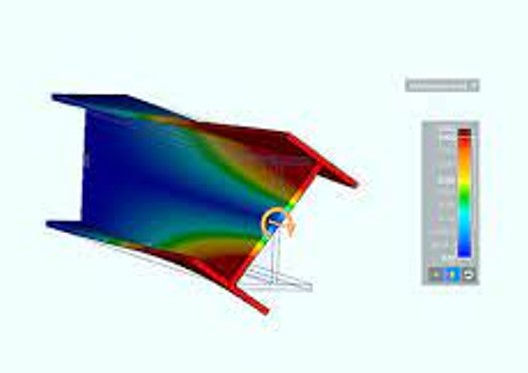

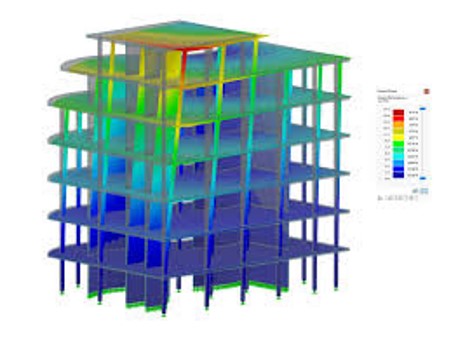

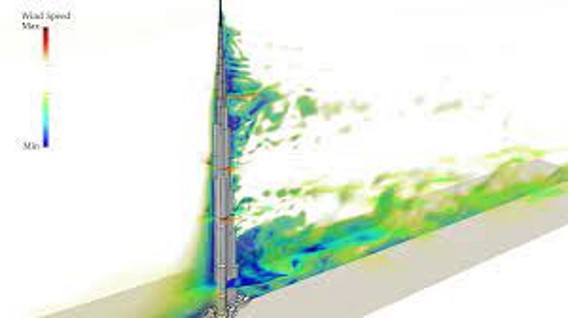

POPUlAR CAE TECHNIQUES

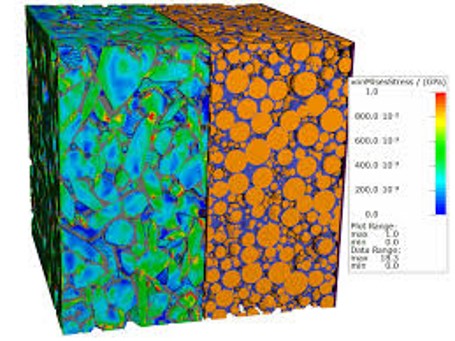

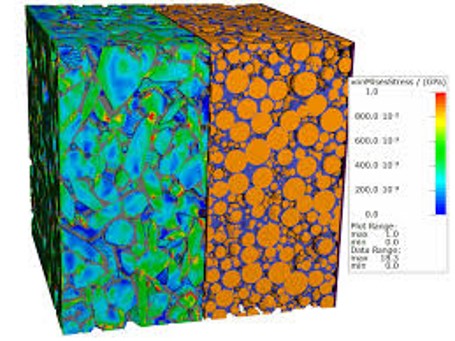

MULTIPHYSICS SIMULATIONS

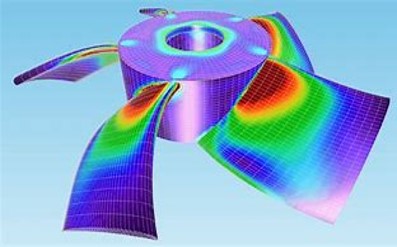

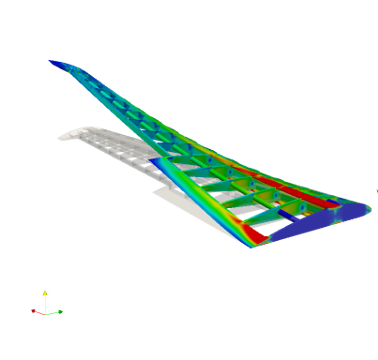

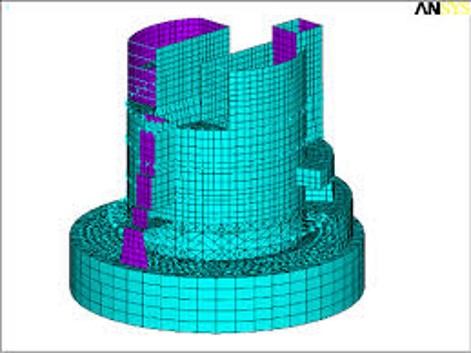

FINITE ELEMENT ANALYSIS (FEA)

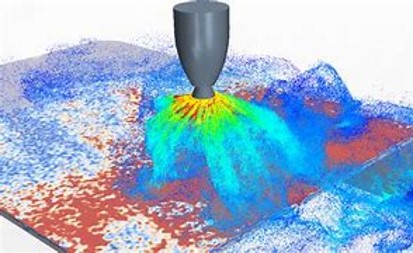

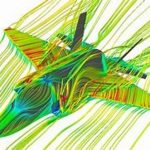

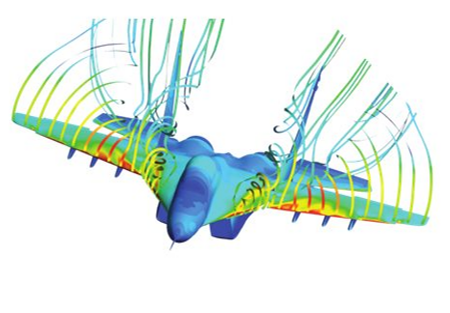

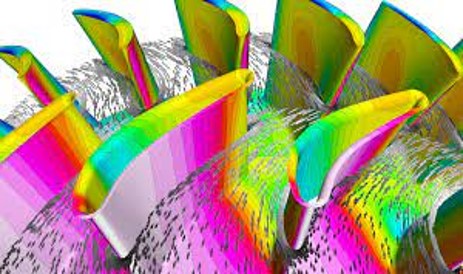

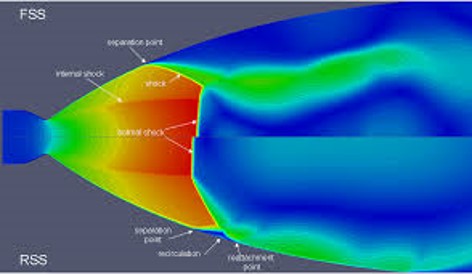

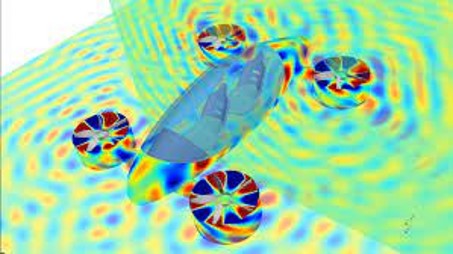

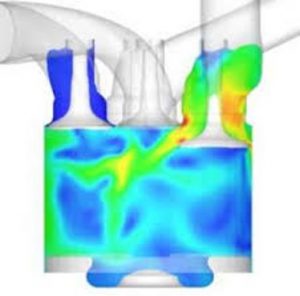

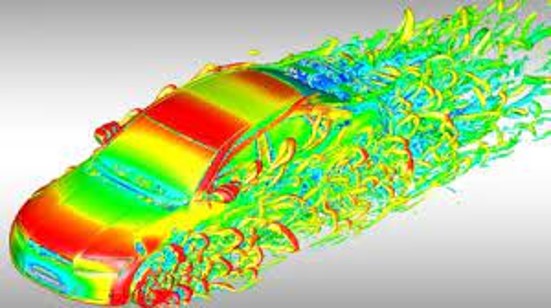

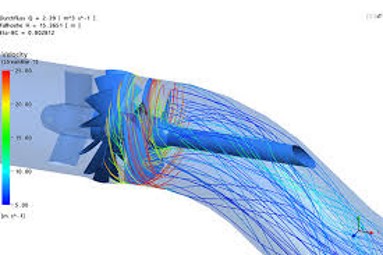

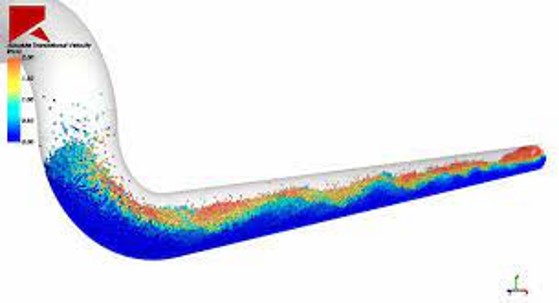

COMPUTATIONAL FLUID DYNAMICS

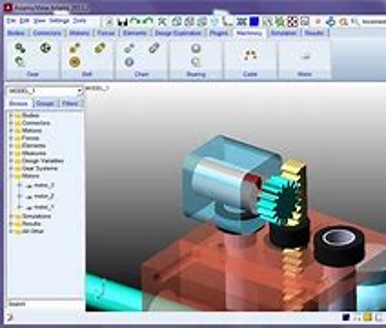

MULTIBODY DYNAMICS

Resources Required for CAE/cfd Implementation

HIGH PERFORMANCE COMPUTERS

SIMULATION SOFTWARE

SKILLED MANPOWER

Industries Benefiting from CAE Services

Aerospace and Defense

Automotive

Electronics

Energy

Healthcare

Architecture and Construction (HVAC)

Marine and Shipbuilding

CAE Services for Aerospace and Defense

Structural Analysis of Aircraft Components

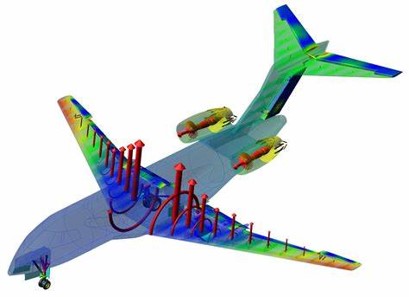

Multibody Dynamics Simulation

Aerodynamic Simulations

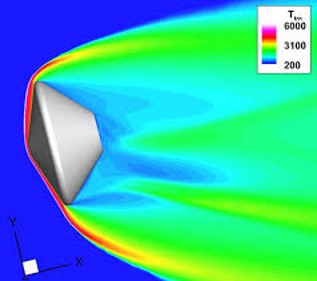

Thermal Analysis of Spacecraft

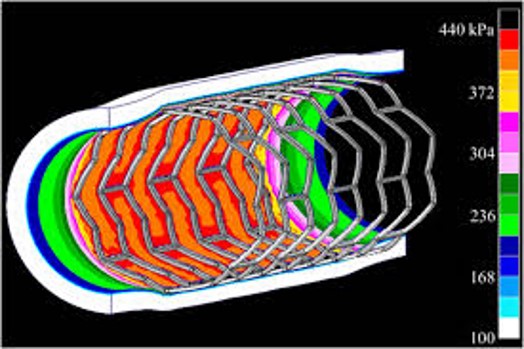

Aerothermal/Combustion Analysis of Jet Engines

Aerothermal/Combustions Analysis of Rocket Engines

Noise and Vibration Analysis

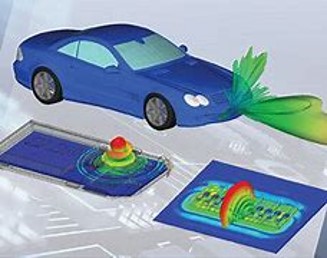

Radar System Simulation

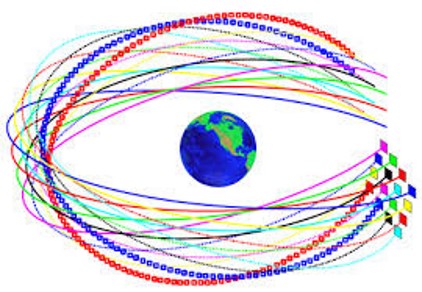

Spacecraft Dynamics and Trajectory Design

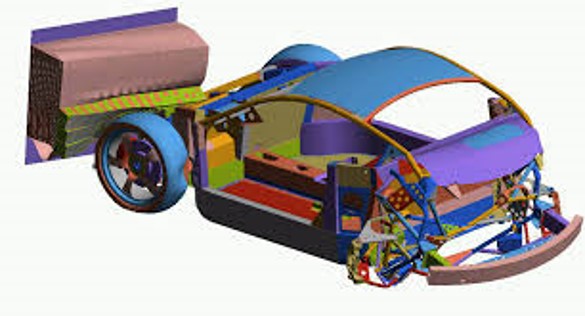

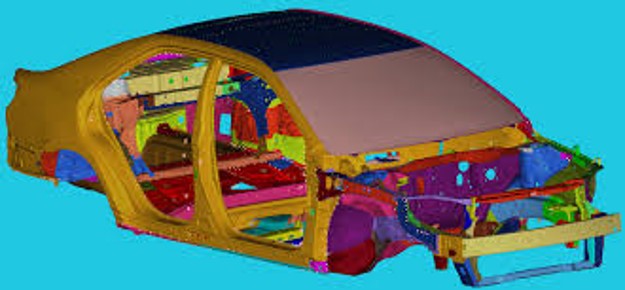

CAE Services for Automotive Industry

Vehicle Crash Testing and Simulation

Noise, Vibration, and Harshness Analysis

Engine Performance and Efficiency Analysis

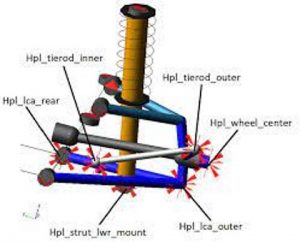

Suspension and Handling Optimization

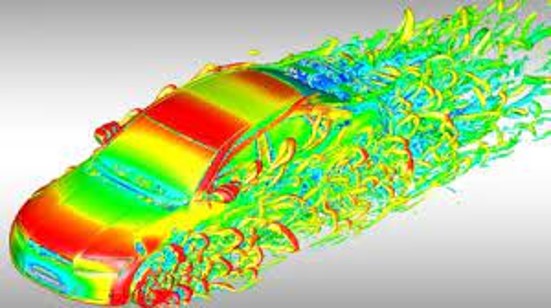

Fluid Dynamics Simulations

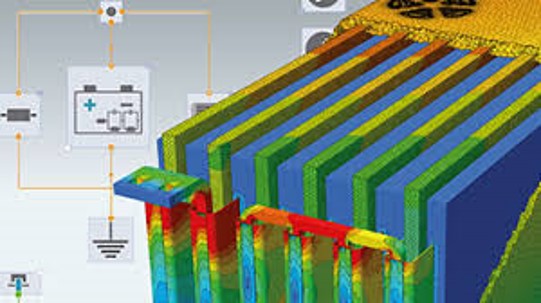

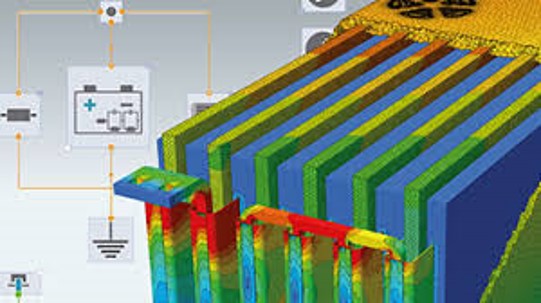

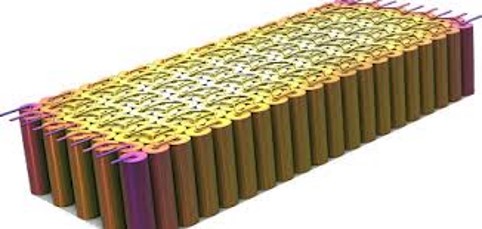

Battery Thermal Runaway

Battery System Optimization

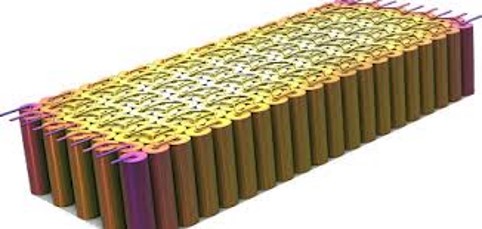

Battery Design

CAE Services for Electronics and Semiconductor Industry

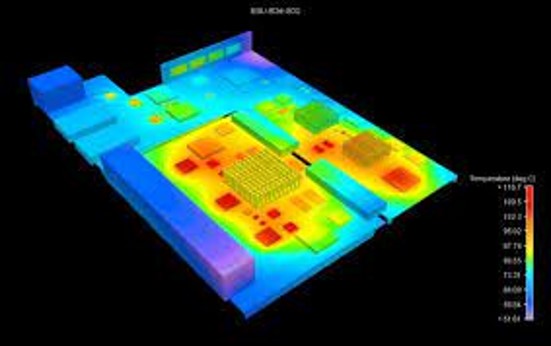

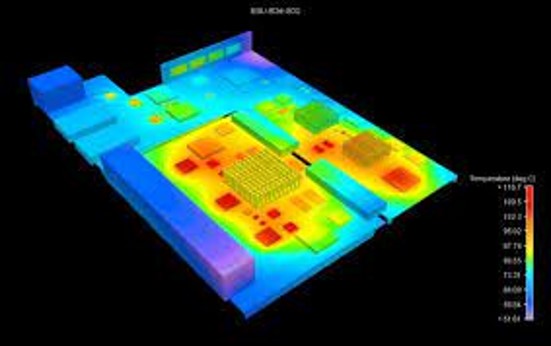

Thermal Management for Electronics

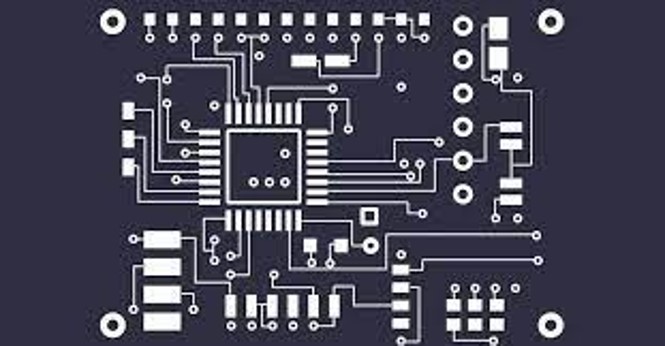

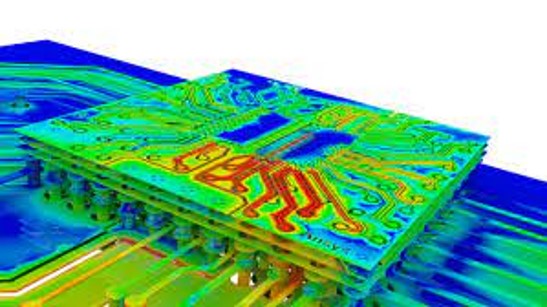

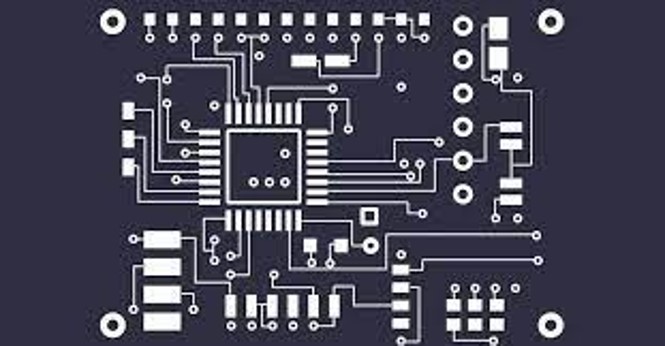

Circuit and PCB Design Analysis

Electromagnetic Interference Analysis

Chip and Semiconductor Design Optimization

Fluid Dynamics Simulations

Battery Thermal Runaway

Battery System Optimization

Battery Design

CAE Services for ENERGY APPLICATIONS

Thermal Management for Electronics

Circuit and PCB Design Analysis

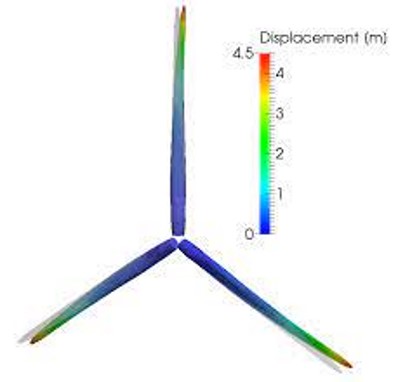

Fluid Structures Interaction in Wind Turbines

Design and Performance Analysis of Wind Turbines

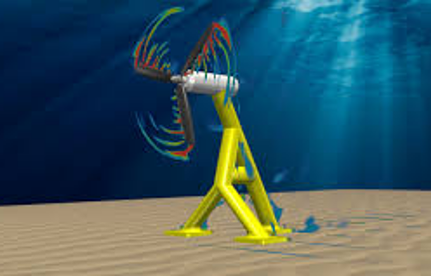

Performance of Hydro-Turbines

Wave/Tidal Energy Simulations

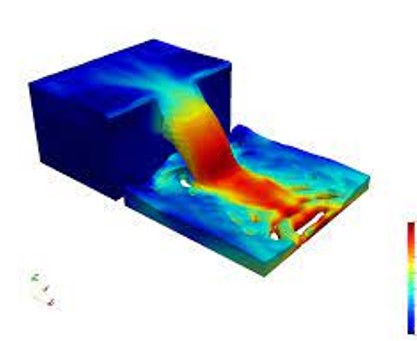

Dam break simulation

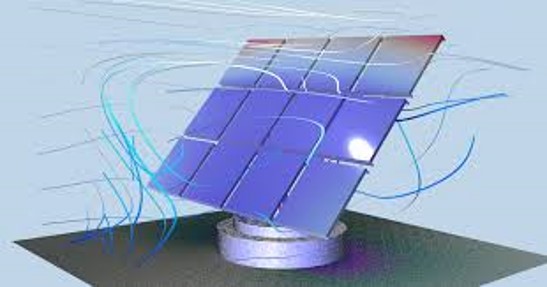

Solar Panel Design

Solar Radiation Simulation

Structural Analysis of Powerplants

Fluid Flow Analysis in Pipelines

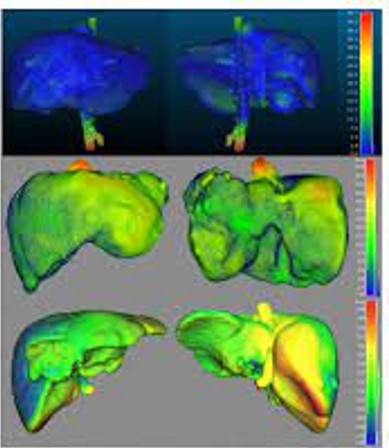

CAE Services for Healthcare and Medical Devices

Biomechanical Analysis for Implants

Medical Equipment Durability Analysis

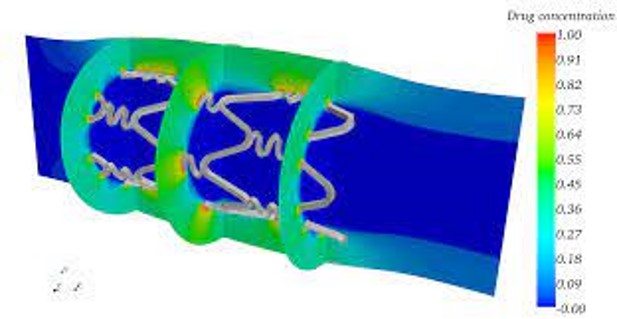

Drug Delivery System Optimization

Patient-Specific Simulations for Surgical Planning

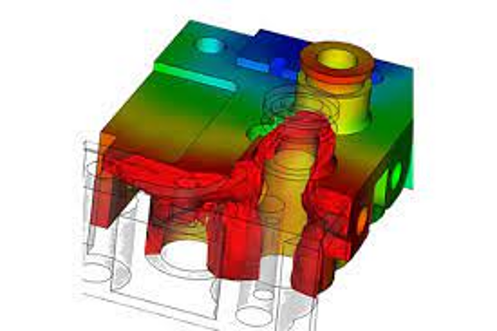

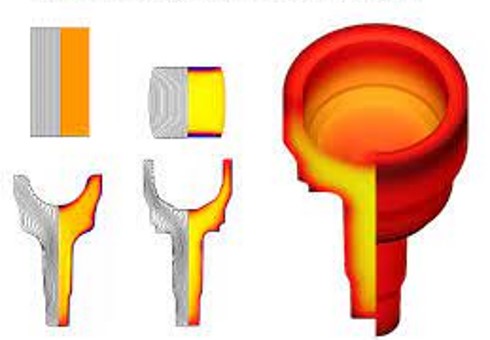

CAE Services for Consumer Goods and Manufacturing

Mold Flow Analysis for Injection Molding

Forging Process Simulations

Product Durability Testing

Materials Selection for Consumer Products

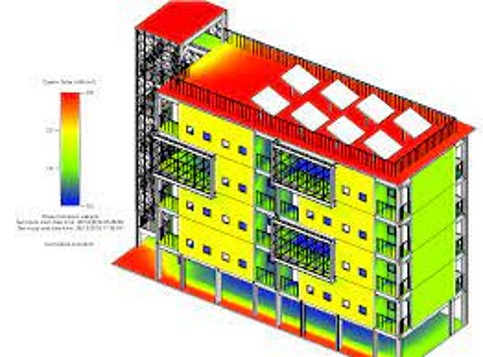

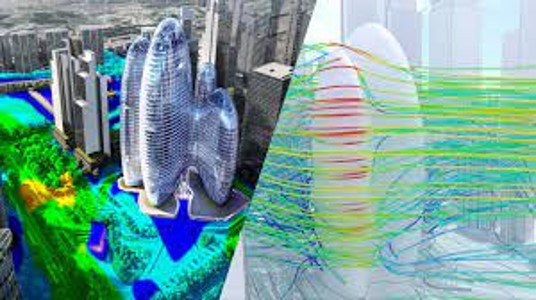

CAE Services for Architecture and Construction

Structural Integrity Analysis of Buildings

HVAC System Efficiency Simulations

Wind Load Analysis of Tall Buildings

Energy Consumption Analysis for Sustainable Designs

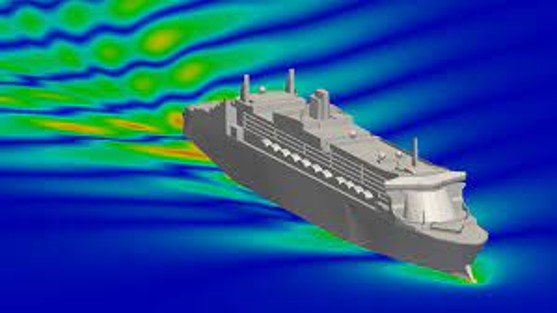

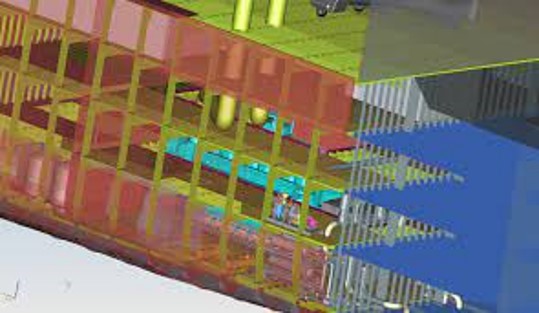

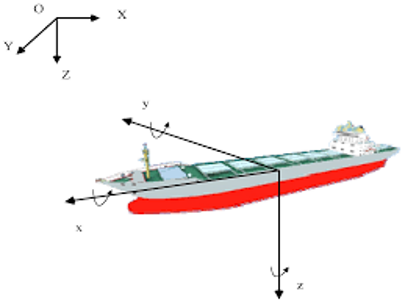

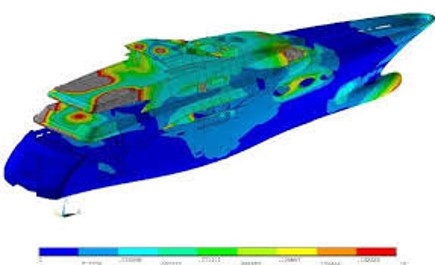

CAE Services for Marine and Shipbuilding

Hydrodynamics Simulation for Ship Design

Structural Analysis for Ship Components

Stability and Maneuverability Analysis

Noise and Vibration Analysis for Cruise Ships

Corrosion and Fatigue Analysis for Offshore Structures

Benefits of Using CAE Services

- Faster Time-to-Market

- Reduced Costs

- Improved Product Reliability

- Enhanced Innovation

- Environmental Sustainability